LoomLab Development Roadmap

Our journey from alpha prototype to production-ready harness engineering platform

Alpha Development Status

LoomLab's foundation is complete and operational. The alpha platform already delivers a functional, performant environment for early harness design work, with the core engine ready for expansion into validation, manufacturing, and digital-twin workflows.

Design Canvas Foundation — Working

A modern, GPU-accelerated canvas built specifically for complex harness layouts.

- Canvas Engine – Full support for zoom, pan, selection, and high-performance rendering

- Component Library v0.1 – Early catalog with connectors, nodes, and mounting elements

- Component Placement – Click-to-place is stable; drag-and-drop is under active development

- Canvas Metrics & Debug Tools – Real-time canvas inspection for engineering QA

- YAML Import / Export – Reliable project interchange for versioning and AI-assisted workflows

- Net Management System – Create, name, and track nets across components and conductors

- Routing Architecture—internal system for conductor path planning, bend logic, and constraint management

- CAN + HV Architecture Modeling – Early schema support for multi-bus, multi-voltage systems

Status: Alpha foundation validated and progressing toward full routing intelligence.

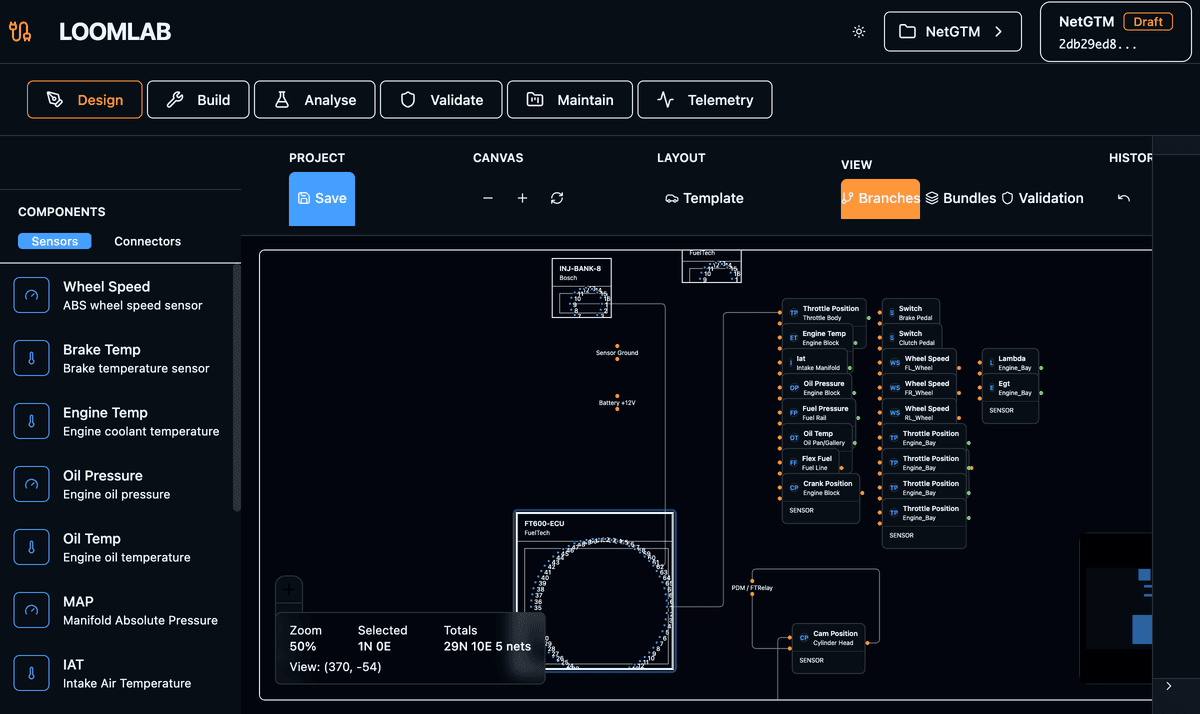

Alpha Preview — Real Canvas Output

Interactive Design Canvas (Alpha)

The interactive canvas is now fully operational in its foundational form.

Core Alpha Features

- • High-performance zoom & pan with no lag across large harness diagrams

- • Component selection & manipulation with precise control

- • Basic placement workflows for building early harness sketches

- • Net creation and visualization through clean, structured data models

In Progress

- • Drag + Drop with Snap-To-Grid for faster layout workflows

- • Routing Architecture—internal system for conductor path planning, bend logic, and constraint management

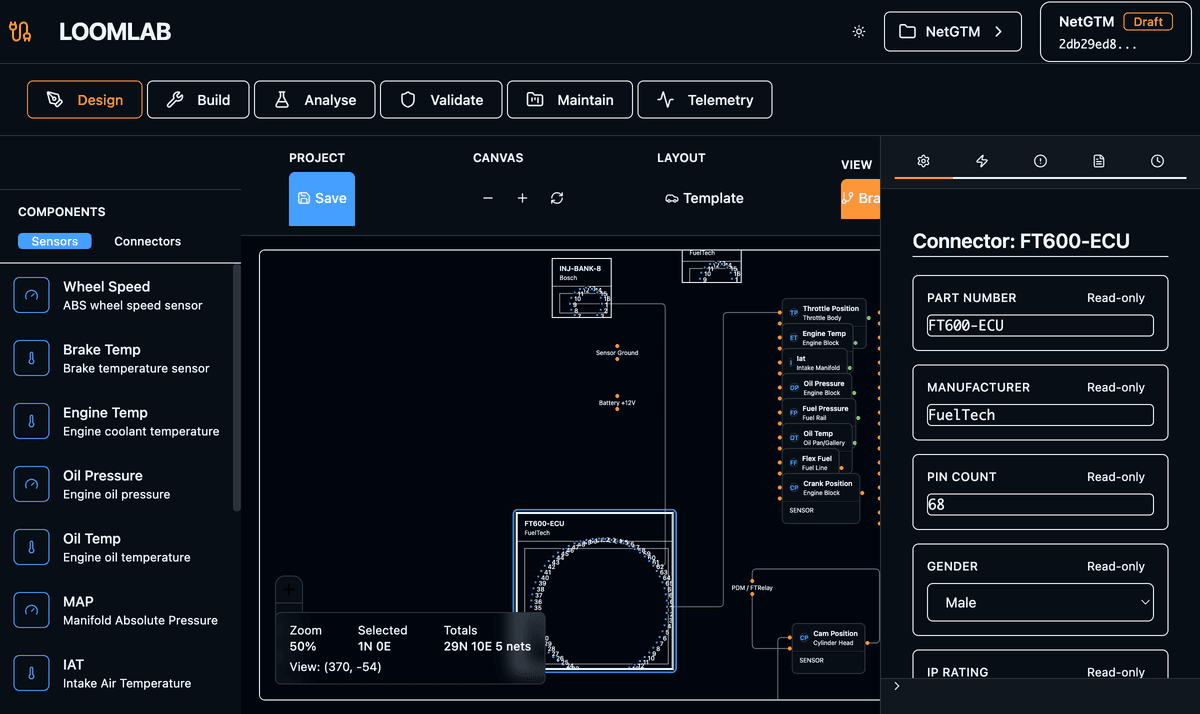

Alpha Preview — Component Selection Working

Planned for Beta

- • Intelligent Routing Engine

- • Automatic conductor routing

- • Collision + intersection detection

- • Bend constraints and manufacturability rules

- • Professional layout optimization for dense harnesses

Real-Time Validation Engine (Beta Target)

A central pillar of LoomLab: live engineering validation as you design.

Under Development

Ampacity Calculations

Real-time current-carrying capacity checks per conductor, including temperature rise and bundling effects.

Voltage Drop Simulation

Automated end-to-end voltage drop analysis based on conductor length, load, and design parameters.

Planned Post-Beta

EMI / EMC Compliance Framework

Crosstalk prediction, shielding rules, and proximity constraints.

Status: Architecture complete; implementation targeted for Beta 2025.

Alpha Preview — Debug Tools Working

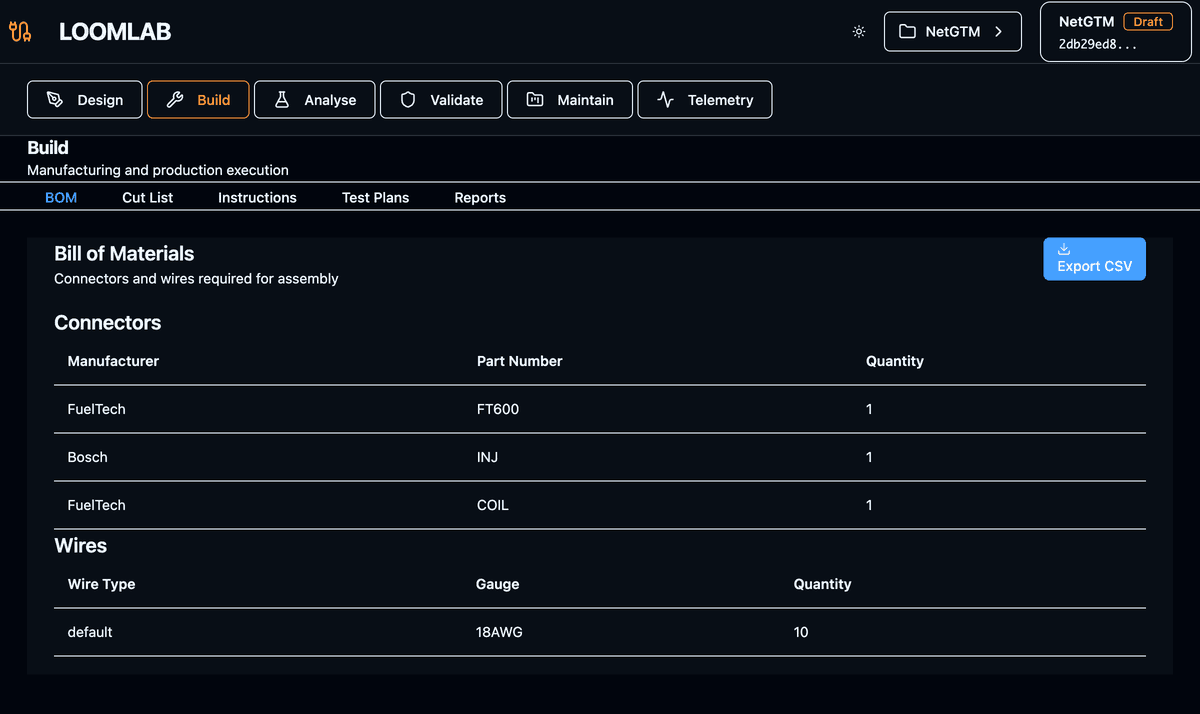

Manufacturing Documentation (Future Release)

Transforming a finished design into a production-ready harness package.

Planned Deliverables

- Automatic Bill of Materials (BOM)

Quantities, part numbers, terminals, tooling, and inventory integration. - Wire Cut Lists

Accurate lengths, gauges, start/end pin data, and conductor metadata. - Assembly Instructions

Step-by-step manufacturing workflow with routing, branching, and connector orientation.

Status: Scheduled for post-validation phase; foundational data models already in development.

Alpha Preview — Export Menu Working

Target Applications

LoomLab is purpose-built for markets where reliability, weight, validation, and documentation standards are critical

High-Performance Racing

Full-vehicle harness design supporting high-density Autosport connectors, CANbus integration, and sensor networks.

Target: 200+ conductors; reduce engineering cycle time by 50%

Marine Autonomous Systems (ROV/AUV/USV)

Robust power, signal, and NMEA2000 architectures with focus on subsea-grade connectors and waterproof routing constraints.

Our Competitive Moat

Aerospace & Advanced Robotics

Lightweight and redundant harness design with precise validation, EMI shielding rules, and weight optimization models.

Long-Term Goal: Route-weight optimization and redundancy validation for safety-critical systems

Development Timeline

1. Alpha Development (Now → Q1 2025)

Building the full foundational system including the design canvas, component library, and structured data models.

Current Focus: Drag-and-drop placement, routing architecture, and validation engine scaffolding.

2. Beta Release (Q2 → Q4 2025)

The feature-complete engineering platform.

Expected Beta Features:

- Real-time electrical validation

- Intelligent routing engine

- Manufacturing documentation tools

- Collaboration features and cloud workspace

- Expanded component library with automotive, marine, and aerospace profiles

Next Major Milestone: Beta canvas + live validation.

3. Production-Ready Platform (2026+)

Enterprise-grade tooling for professional harness engineering teams.

Future Vision:

- 3D routing tools compatible with motorsport, aerospace and robotics packaging

- Advanced EMI/EMC compliance engine

- Digital twin integration for full lifecycle management

- Cloud workflows, inventory integration, test-bench interfaces, and CAN diagnostics

- AI-assisted auto-routing and anomaly detection

Ready to shape the future of harness engineering?

Join our early access program and help guide the next generation of professional wiring-system design tools.